Brinox Ltd.

Passivation of stainless steel

About the company and the project impact

A company with more than thirty-five years of experience in offering complete turnkey solutions and equipment for the pharmaceutical, biopharmaceutical, and food industries saw the opportunity to improve their production process within the KET4CleanProduction pilot project.

The project had the greatest impact on gaining new insights on the influence of various surface passivation procedures on surface chemical composition, morphology, and most importantly, corrosion resistance of stainless steels used by the company. The systematic studies conducted during the project are important for optimising the company's in-house passivation process, as well as for potential use of novel environmentally friendly approaches based on gaseous plasma treatment, which are intriguing and could be used in the near future. The project provided the company with an insight into the implementation of less harmful chemicals for chemical passivation of the surface, including a shortened treatment time, which reduces the manufacturing costs and carbon footprint of the end product.

Brinox,Slovenia | www.brinox.eu

KET Technology

- Advanced materials

Countries involved

- Hungary

- Slovenia

Outcome

Due to the project, the company was able to implement less harmful chemicals for chemical passivation of the surface, including a shortened treatment time, which reduces the manufacturing costs and carbon footprint of the end product.

Using the knowledge of the selected experts in the field of surface treatments and analysis, they relatively quickly achieved a better quality of their final products. The cooperation with the selected institutes within the frame of the KET4CleanProduction pilot project represents an excellent basis for further collaboration in the already initiated development of less aggressive techniques, such as plasma passivation.

Video

Before

Vessel before chemical treatment

After

Vessel after chemical passivation

Key success factors

For Brinox, the key project success factors were the selection of skilled professionals with many years of expertise in the aforementioned technological field, who were able to administer their knowledge outside the framework of the institute - in real industrial applications.

The necessary analytical equipment, which was provided by the technology centres, helped to evaluate the results and properly direct the project towards the set goals.

Corresponding KETs Technology Centre:

Bay Zoltan Nonprofit Ltd. | Budapest, Hungary

Institute Jožef Stefan | Ljubljana, Slovenia

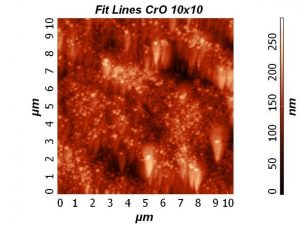

Surface of stainless steel after plasma treatment

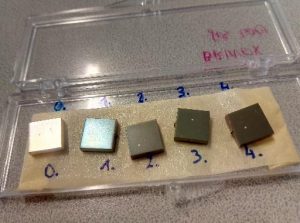

Samples treated at different plasma conditions

'It was a great experience to apply research methods to industrial scale.'

'The project has helped us to improve technological development of our company.'