Knot Kft.

Flow optimisation and surface treatment of water flow turbines

About the company and the project impact

Knot, a privately-owned limited company is a water utility construction and maintenance company that serves water utilities and other markets. Furthermore, Knot Kft. independently develops new technologies for the Cleantech industry. Knot Kft. has developed an innovative, in-line, brushless generator prototype that can be integrated into the local water network to generate small but steady amounts of electricity. The prototype, named WP4F, is a standalone unit located between the flanges. It, therefore, works in smaller diameter piping and can be set up in the exact place where electricity is needed.

Since the prototype is installed in piping networks, it is of paramount importance to have a coating that meets the drinking water standards and simultaneously prevents the formation of deposits. The hydraulics optimisation presents a challenge because the prototype is currently optimised for a given water velocity, but the generator needs to adapt to varying water velocities in the network. The KET4CleanProduction pilot project allowed the company to develop cost-effective and competitive turbine manufacturing procedures, as well as to get familiar with cutting edge technologies in surface material development, and all that in cooperation with KET TCs.

Knot Kft.,Hungary |www.knot.huKET Technology

- Advanced Materials

- Advanced Manufacturing

Countries involved

- Hungary

- Germany

Outcome

In attaining their key objectives, the company encountered countless problems, as well as solutions, which provided an exceptional opportunity for development.

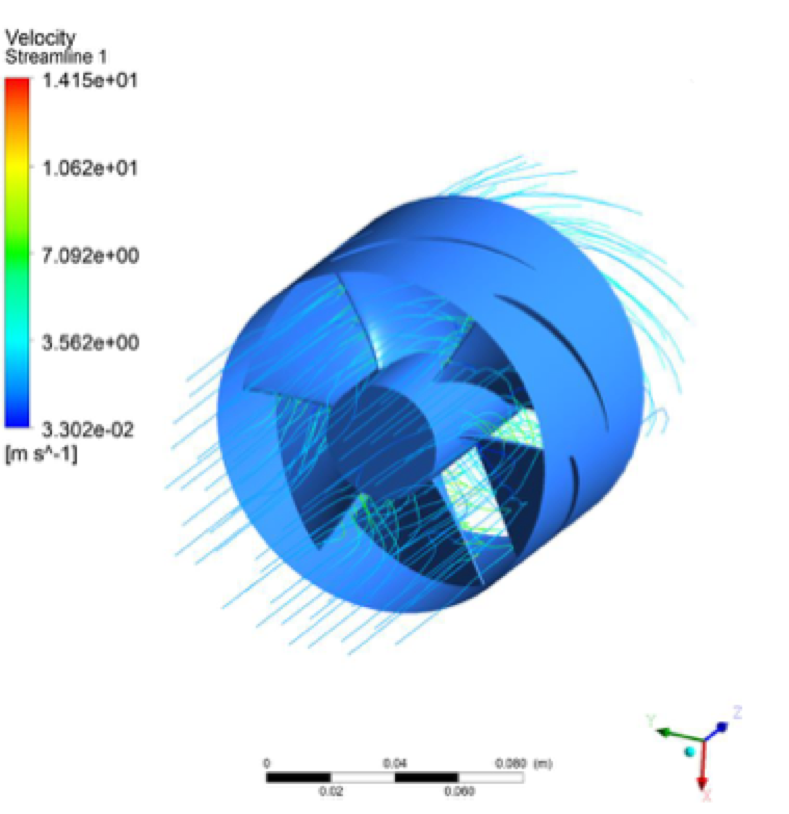

Knot Kft. has acquired simulation technology and expertise to map the wide range of planned turbine applications, saving time and money during the project. The cooperation with KET TCs allowed the Knot company to develop and test surface treatments that are essential for both the manufacturing process and the product itself. The whole process increased the competitiveness of the product. The help of the simulations concerning the rotor design led to the achievement of better torque values from a given water system.

Test tube implementation

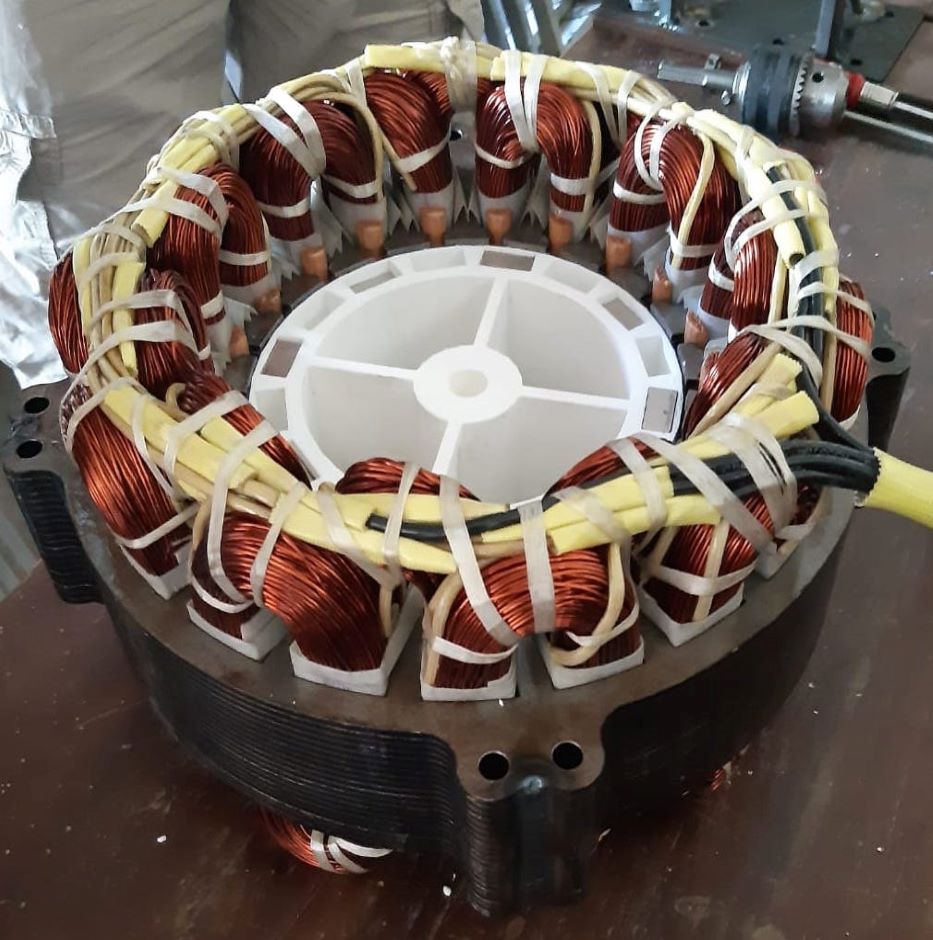

Generator with iron core and turbine

Turbine modeling results

Key success factors

The key success factor was the relationship between the company and the KET TCs.

The cooperation helped to change the attitude of the teams towards the implementation of domestic and international development projects, which gave the company a competitive advantage. Personal and professional relationships between the companies were strengthened, and the cooperation between all three parties will continue in the future as well.

Corresponding KETs Technology Centre:

Bay Zoltán Nonprofit Ltd. for Applied Research | Budapest, Hungary

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V. | Stuttgart, Germany