KEKO Equipment

Developing a new clean manufacturing process for ceramic pressure sensors

About the company and the project impact

KEKO Equipment Ltd., an electronic equipment manufacturer from Slovenia, is a leader in the manufacture of machines for the production of multilayer passive ceramic components. The company is also a producer of LTCC materials and equipment for the production of multilayer ceramic components.

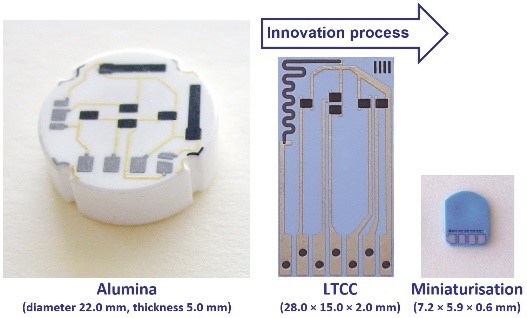

Within the Project, piezoresistive type ceramic pressure sensor element was designed, developed and successfully tested. It was also proved that the approach of using LTCC technology allows fabricating pressure sensors for temperatures up to 500 °C. The novelty in the Project was the use of LTCC technology with significantly lower energy consumption in the manufacturing process, in comparison with the conventional alumina technology. Compared to the conventional alumina-based CPSs, the use of LTCC materials and technology leads to lower energy consumption and miniaturization due to mechanical properties and flexible design. That allows lower energy consumption, lower material consumption and, consequently, a smaller generation of waste and pollution.

KEKO Equipment Ltd., Slovenia | www.keko-equipment.comKET Technology

- Advanced Manufacturing

- Advanced Materials

- Nanotechnology

Countries involved

- Slovenia

- Germany

Outcome

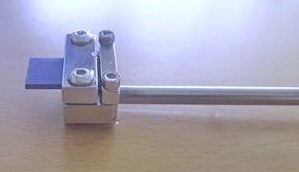

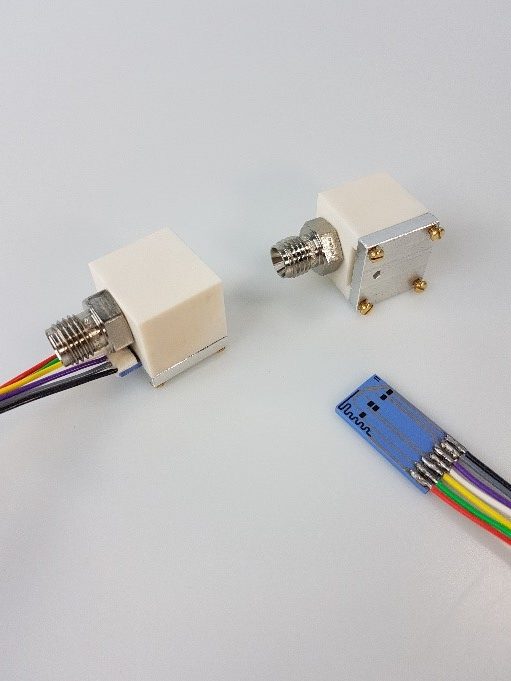

An assembly process for operating temperatures up to 250 °C, instead of initially planned 180 °C, was successfully developed and demonstrated. The MGP team significantly exceeded the planned target, which means a breakthrough, as there is almost no sensor for this temperature range on the open market.

It is based on Teflon wires soldered to the sensor with a special solder but also a sensor package that allows this temperature. For higher temperatures, the special metal holder was designed for testing the sensor's properties in temperatures up to 500 °C, and even over-temperature up to 700 °C. Several demonstration ceramic pressure sensors were manufactured and characterized. Some of them are equipped with a dedicated developed readout electronic circuit. At the same time, the LTCC material was investigated, and the manufacturing process was optimized to fabricate 3D structures with lower energy and material consumption.

LTCC-based ceramic pressure sensor designed for operating at temperatures up to 200 or 250 °C

Key success factors

The key success factors were the right choice of partners with the expertise, experience and available equipment fitted for the technical solution for the challenges faced by the SME, as well as the commitment of all three partners to the project objectives.

Both the expertise, equipment and mutual trust between partners, as well as their experience, played a very significant and important role in the project implementation. That is also reflected in the fact that the partners are ready to cooperate in the future.

Success story video

Corresponding KETs Technology Centre:

Institute Jožef Stefan | Ljubljana, Slovenia

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V| Stuttgart, Germany