EMO Orodjarna d.o.o.

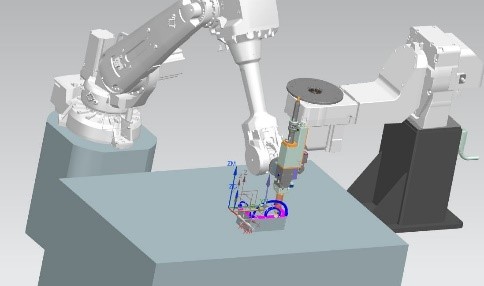

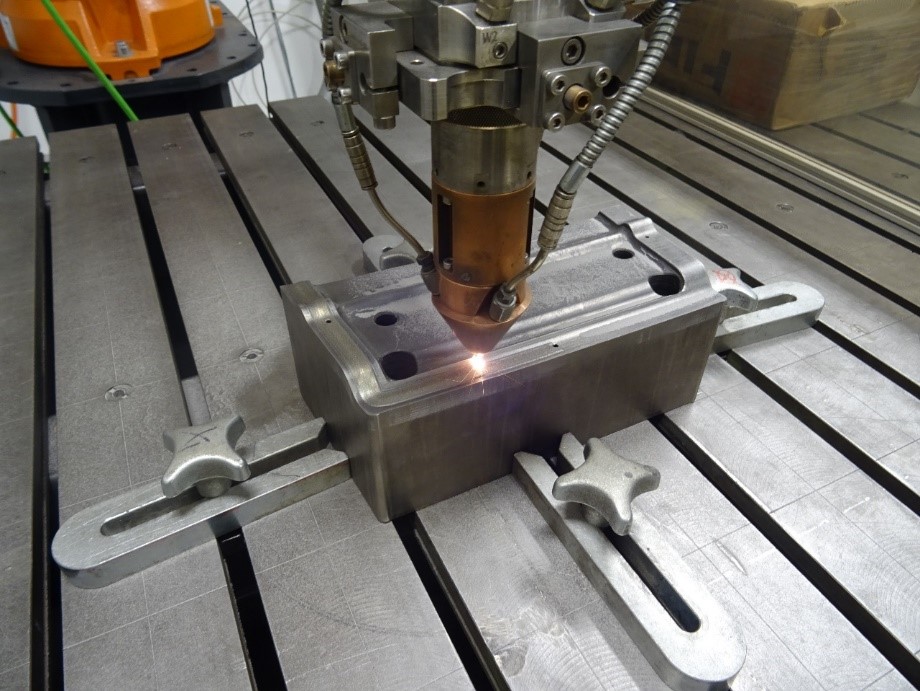

Advanced tool coating for automotive industry by laser cladding (HiTool)

About the company and the project impact

EMO Orodjarna d.o.o. is a Slovenian company specialised in developing, designing and manufacturing tools for sheet metal cold forming for the automotive industry. The company makes transfer, individual, progressive and prototype tools for structural parts for the OEMs such as Porsche, BMW, Audi, Daimler, Skoda, VW, etc. Due to its highly qualified and experienced engineers, vast knowledge and constant investments in state-of-the-art software and equipment, the company provides complete support to its customers. EMO Orodjarna applies an innovative and market-based approach. It is committed to consistent development according to the customer needs and the interests of all participants in the toolmaking process.

The company applied for a micro-grant within the KET4CleanProduction project to reduce production costs by finding an adequate solution for manufacturing cheaper and more environmentally friendly moulds.

EMO Orodjarna d.o.o., Slovenia | www.emoorodjarna.comKET Technology

- Photonics

- Advanced Materials

- Advanced Manufacturing

Countries involved

- Slovenia

- Austria

- Italy

Outcome

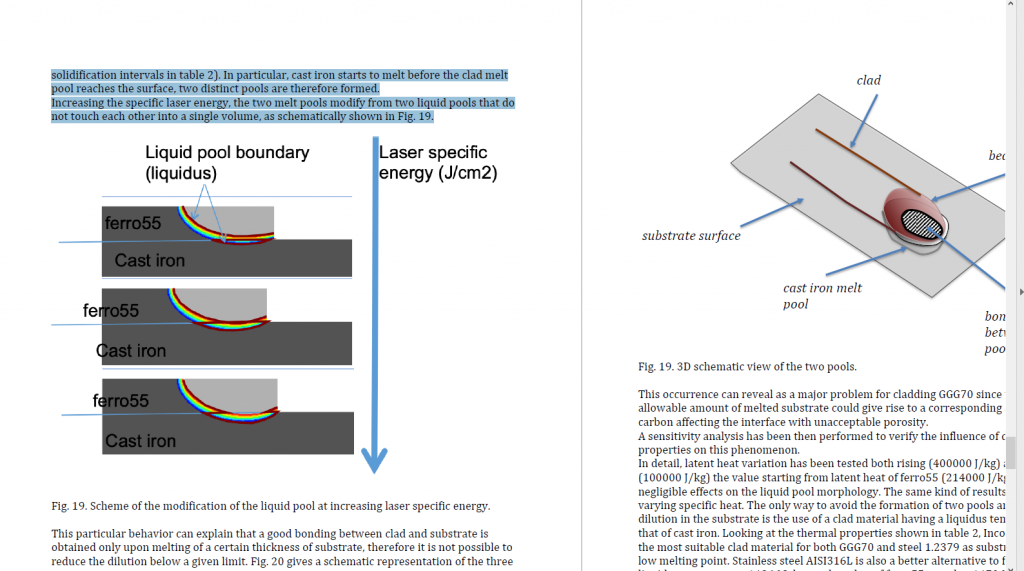

The cooperation with the KET TCs has resulted in the implementation of high-performance metal coatings over the low-cost substrates, which will enable the manufacturing and repair of cheaper and more environmentally friendly moulds. The combinations of 1.2379 substrates with the Ferro 55 and H13 will allow the production of moulds with sufficient hardness and significantly reduced costs for automotive tooling. Furthermore, it will reduce the usage of hard coatings that contain Critical Raw Materials (CRM) to a minimally necessary level required by the functionality.

EMO Orodjarna benefitted from the newly acquired knowledge related to the combination of materials with a completely different constitution in the cladding process. Furthermore, it achieved a significant improvement of knowledge on the optimisation of the process parameters search in the cladding process, especially when critical requirements (e.g. low dilution) are required while keeping the quality of the bond between materials. The usage and insight into the thermomechanical simulation modelling was a key factor and an extremely useful new tool for the company.

Key success factors

Even though there were challenges during the implementation of the project, those were all successfully overcome. The KET TCs performed a series of trials, which not only resulted in the best possible solution but also provided significant insight into the physics and metallurgy problems related to the combination of high carbon steel substrates with the high melting temperature coatings.

The efficient and smooth communication between the company and the KET TCs, as well as the expertise of the KET TCs and combined knowledge of the KET TCs and the company, were the key success factors of this project, helping to ensure the successful implementation and sustainability of the project.

Corresponding KETs Technology Centre:

Joanneum Research | Graz, Austria

Seamthesis Srl | Piacenza, Italy