Engineering Team

Novel technological solution for soles for cyclist footwear made of two completely recyclable materials

About the company and the project impact

Engineering Team is an Italian company founded in 2001. It focuses on providing companies with design, conception, prototyping, and industrialisation for new products in various sectors. The company implements new innovative materials such as biopolymers and various composite materials. The company is also the owner of brands in the sportswear and footwear sector, with its patented air recirculation system.

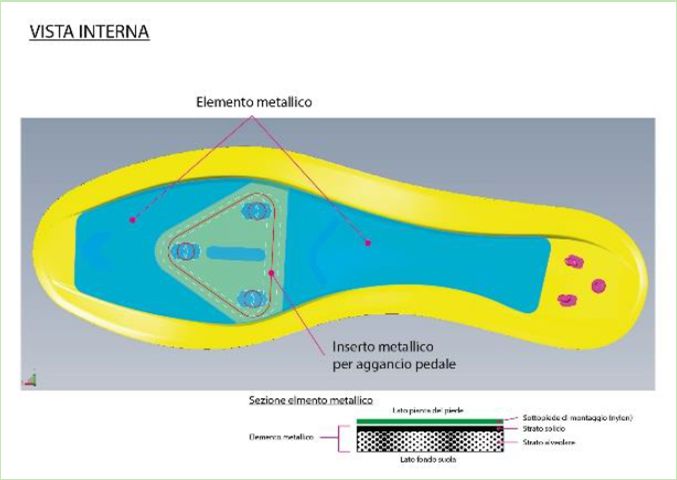

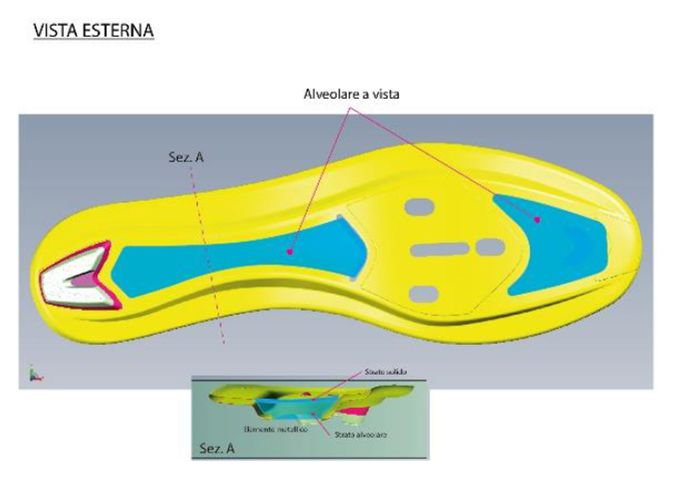

Cyclist footwear is currently made from materials that are not fully recyclable; in particular, technical footwear uses carbon soles made from fabrics and resins derived from oil, which cannot be recycled but are burned at waste treatment plants. The KET4CleanProduction helped the company to resolve its main objective, more precisely, to develop a new type of sole for cyclist footwear having the same technical performance of a carbon sole, using completely recyclable plastic polymers reinforced with a light metallic structure produced by additive manufacture.

Engineering Team S.R.L., Italy | www.engineeringteam.comKET Technology

- Advanced Materials

Countries involved

- Italy

- Austria

Outcome

The redesigned sole with the new geometry and materials was simulated mechanically under the same load and constrain condition of the original part made in carbon fibre. It demonstrated that mechanical behaviour is equivalent in terms of stress state and deformation, as well as the maximum displacement, which occurs at the heel. Thus, comfort is expected to be the same. Titanium grade 5 (Ti6Al4V) raw material is used in the form of metal powder. Polycarbonate/Acrylonitrile butadiene styrene (PC-ABS) was extruded with the minimum quantity to create the part. So, no scraps were created in both cases. Another benefit gained by the use of Additive Manufacturing is the complete elimination of the oil for lubrication and for the processes that are mandatory in the creation of moulds.

In the new process, there is no need for tooling and consumables to be disposed of, in full respect of the environment (green shoes). Furthermore, the gained freedom of design determines the possibility to manufacture different parts with different shapes, and workers will not be exposed to solvents and resins vapours.

Key success factors

The use of Key Enabling Technologies with adequate sensibility drastically changes/improves products, processes and manufacturing operations to achieve many different goals.

The elimination of potentially harmful raw materials and substances that somehow enter the process determines a better workplace, safer for workers and the environment. The positive consequence is in terms of higher product quality because of the highly controlled technical systems used (KET). Many of the identified implementation points have been successfully reached, so future steps for final industrial deployment of the innovative manufacturing process and related product are under discussion among the partners.

Corresponding KETs Technology Centre:

Seamthesis Srl | Piacenza, Italy

Joanneum Research | Graz, Austria