AMG Technology Ltd.

Functionalized Microcantilever Sensors for Air Quality Monitoring

About the company and the project impact

AMG Technology, an independent small enterprise founded in 2007, is a developer and supplier of silicon self-sensing cantilevers. The scope of applications ranges from advanced analytical instruments, such as the AFM and correlative microscopies, to the detection of specific chemicals and antibodies. The company's core business is the development of integrated MEMS capable of bridging the gap between nano-sized objects and macro-level tools, as well as connecting micromechanical systems with electronics.

Background expertise in the functional integration of piezoresistive flexures is the basis for the development of a novel MEMS platform for air quality monitoring. The MEMS device generates multiple electrical signals and individual cantilevers, which, being very closely spaced, are uniformly exposed to the sampled air. The main aim of the KET4CleanProduction Pilot project was to transfer technology for functionalization by post-processing of cantilever array(s) used for reliable assessment of specific air quality parameters. On-chip integration of cantilevers for measurement of different parameters related to Air Quality (AQ) and on-package integration of microfluidic, actuation and interface members, providing dramatically improved performance of the AQ Monitoring sensors, were demonstrated and verified in a lab.

AMG Technology Ltd., Bulgaria| www.amg-t.comKET Technology

- Nanotechnology

- Nano and Microelectronics

Countries involved

- Bulgaria

- Portugal

- Germany

Outcome

Existing technologies and capacities of the partners were successfully fused to demonstrate the advantages of the new technology for the fabrication of AQM sensors, according to the project plan. Technical, ecology and exploitation challenges were successfully met by on-chip integration of cantilevers for measurement of different AQ parameters, and on-package integration of microfluidic, actuation and interface members, altogether providing a dramatically improved performance of the AQM sensors.

Application-specific on-package Bio/Chemical functionalization of individual microcantilevers and arrays with varied patterns was performed and verified. That resulted in 4-6 times reduced costs, power and raw materials, demonstrated and verified. Furthermore, there were >10 times footprint and >10 times power consumption reduction demonstrated as well.

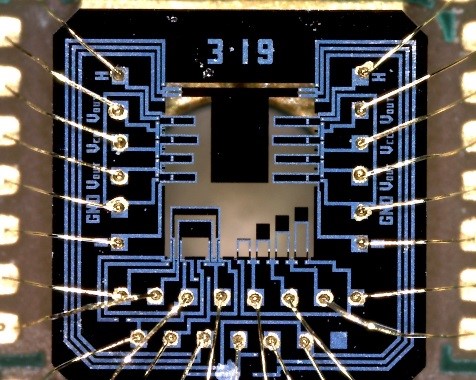

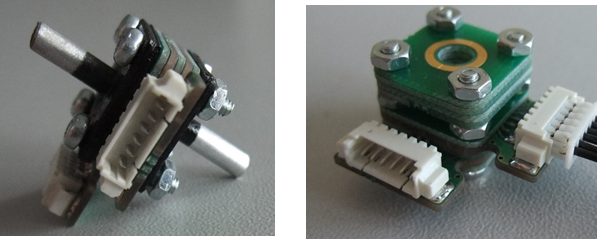

Single sensor chip assembled to carrier

Multi-parameter measuring chip on dedicated PCB carrier

Prototype of self-sensing micro-cantilever sensors for AQ monitoring applications

Key success factors

The key success factors were the parties' expertise and trust between the partners.

The partners shared an understanding of the subjects and learning of new R&D fields, like new product development. The lack of competition in the research area also played a role. Mutual trust between partners played a very significant and decisive role. Therefore, this project can be considered just as a trigger for future joint research.

Success story video

Corresponding KETs Technology Centre:

International Iberian Nanotechnology Laboratory | Braga, Portugal

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V. | Stuttgart, Germany