Archee, s.r.o.

Optimization and sustainable design for clean production of SPEAR hydro

About the company and the project impact

Archee, an SME based in Slovakia, focuses on the design and development of alternative sustainable energy solutions. The main purpose of the company is to develop and produce sustainable energy solutions in energy production and energy use, primarily oriented around low-carbon/ carbon-neutral materials, passive heating, or cooling technologies. The company focuses on bringing cutting-edge innovations to the market in the segment of sustainable energy sources, architecture, and urban design. A SPEAR power plan is currently the company’s main product that is under development, with two variants: SPEAR hydro and SPEAR aero.

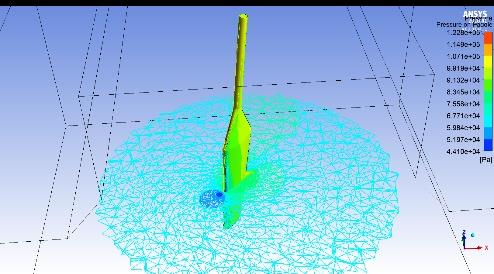

Within the KET4CleanProduction project, the company focused on the optimization of the design for clean production of SPEAR hydro non-rotational energy harvesting power plant. The main improvements are visible in the overall power output, reconfiguration of internal machinery, the introduction of modularity, reduction of raw materials consumption, and the application of environmentally friendly biofouling coating to prevent algae build-up.

Archee, s.r.o., Slovakia | www.archee.techKET Technology

- Advanced Manufacturing

Countries involved

- Slovakia

- Germany

- Portugal

Outcome

Due to the Project, greater efficiency was achieved through the modification of blade design, suspension, and bearing design. Moreover, more cost-effective, sustainable production will need less material. Based on the blade system modification, the entire generator and inside machinery were reconfigured to be deployed within a standardised recycled shipping container. The modification reduced the overall number of components, decreased material consumption, and the complexity of the system. The reconfigured container-generators are easily maintained and replaced.

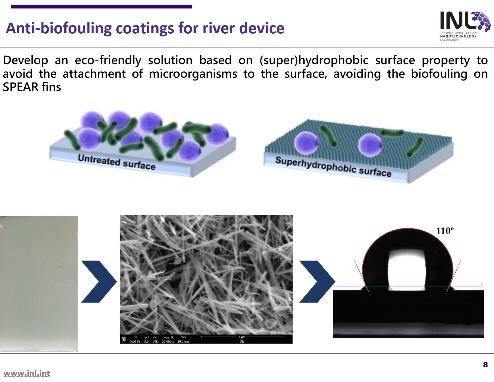

The development of eco-friendly top-coat formulation with biofouling properties will significantly help decrease maintenance and associated costs, as well as increase the number of days per year of continuous operation. The nanocoating is eco-friendly compared to available products on the market and needs to be reapplied less often (with no algae build-up interrupting operation). Standard biofouling coating is toxic to the environment, and therefore, not usable.

Key success factors

The cooperation with the Technology centres provided the startup with key advancements in the overall design of the product, making it more sustainable from both the research and business perspectives.

The primary success factor was the design optimisation of the blade system and the computational fluid dynamics analysis and simulations. Those findings and refinements led to higher efficiency and greater energy output. The optimisation will lead to a more modular design, reducing the consumption of construction materials. Another milestone was the development of a nanocoating used to cover the underneath of the SPEAR mobile power plant. The environmentally friendly nanocoating will remove the chemical hazard to the environment, posed by the current standard coatings, and will reduce the maintenance duration and costs. The research and work conducted during the project have, thus, given the solution a critical sustainability boost.

Corresponding KETs Technology Centre:

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V | Stuttgart, Germany

INL- International Iberian Nanotechnology Laboratory | Braga, Portugal