Gabrijel Aluminium

success story

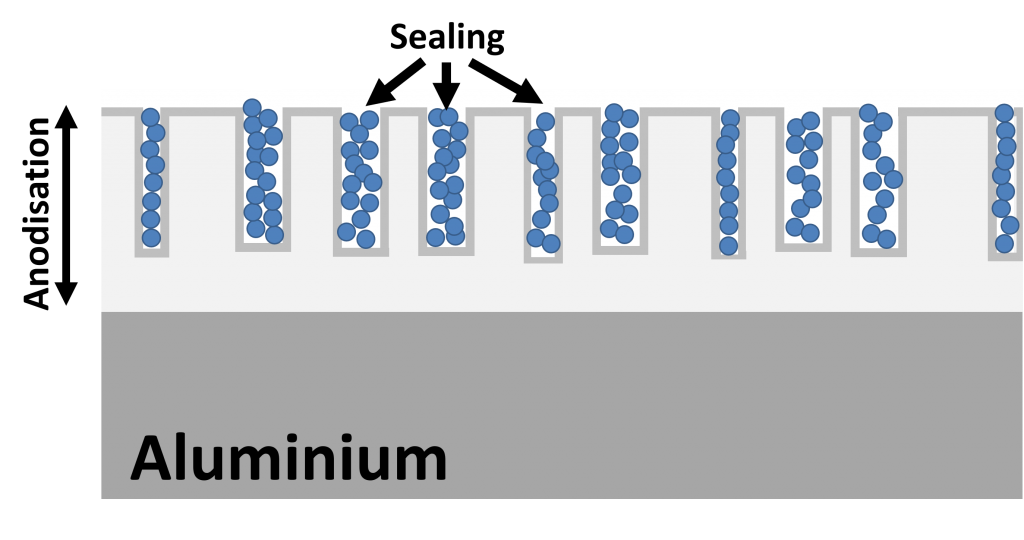

Surface treatment process implementation for aluminium sealing to improve anti-corrosion properties

The Gabrijel Aluminium company is a global-oriented Slovenian company with a successful tradition starting in 1964. The company offers a wide range of high-quality aluminium products, including tailor-made technical and decorative components. With its rich experience and innovative approach, the company assists the customers in the development of their aluminium components, providing them with a comprehensive solution from the idea to the delivery of a quality product.

The company applied for the KET4CleanProduction project intending to optimise and develop a novel technological solution for the anodising and sealing manufacturing of aluminium corrosion protection systems.

KET Technology Centers involved

Josef Stefan Institute | Slovenia

International Iberian Nanotechnology Laboratory | Portugal

The achieved objectives of the Project include the development of the solution by optimising the anodising and sealing; characterisation of the anodising and sealing performance (composition, thickness, durability); development of new alternatives in KET TCs’ laboratories; and the evaluation of corrosion performance of the anodised and sealed aluminium. Such a systematic approach provided qualitative and quantitative indicators of the preparation and final performance.

The key outcomes of this Project are the efficient optimisation of the current manufacturing process and characterisation of the prepared coating systems. The optimised solution is more user-friendly because the process can now be controlled under less strict conditions. Also, the production can be carried out with a reduced amount of used hazardous chemicals.

The key success factor was the combined multidisciplinary knowledge of the company and the KET TCs.

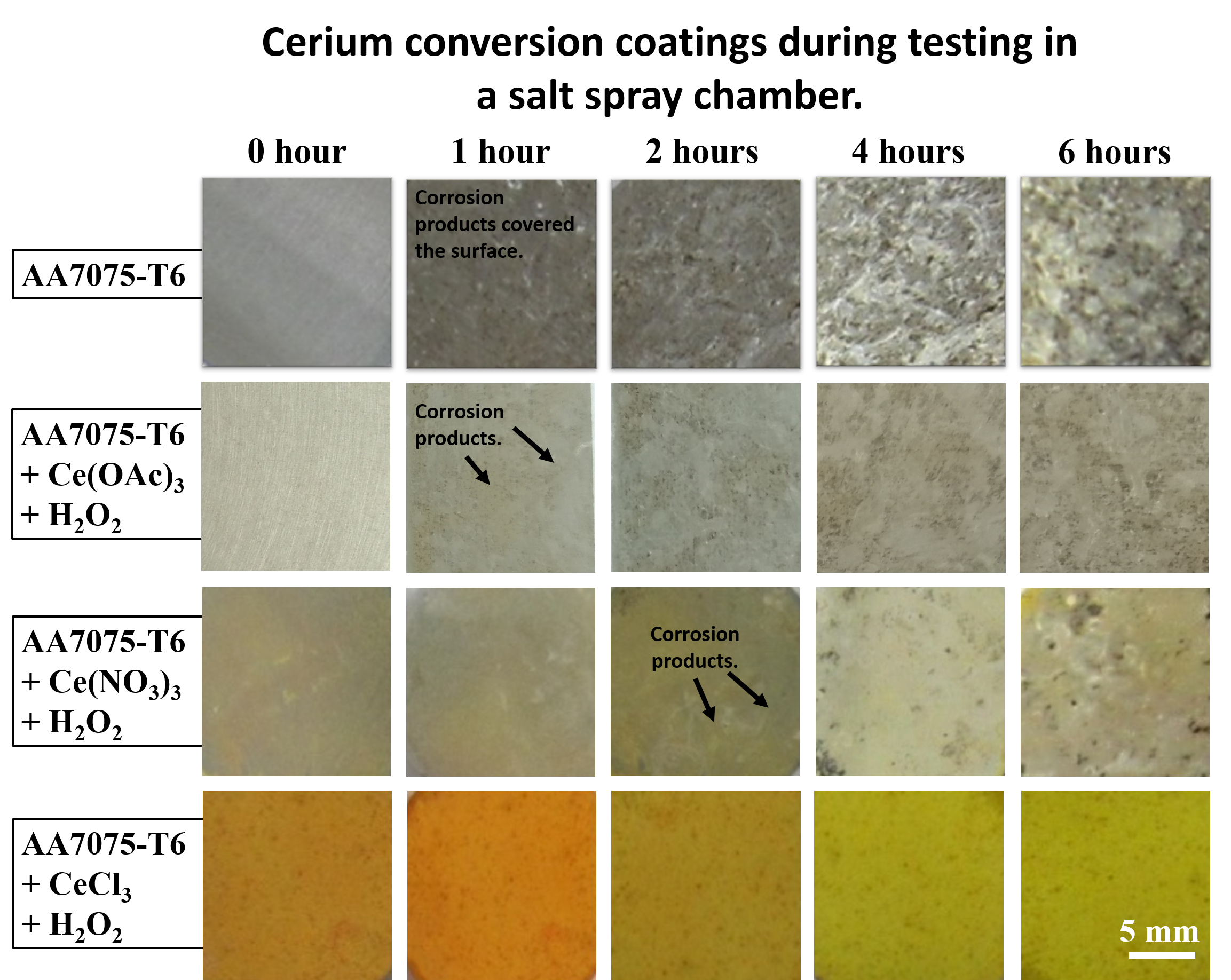

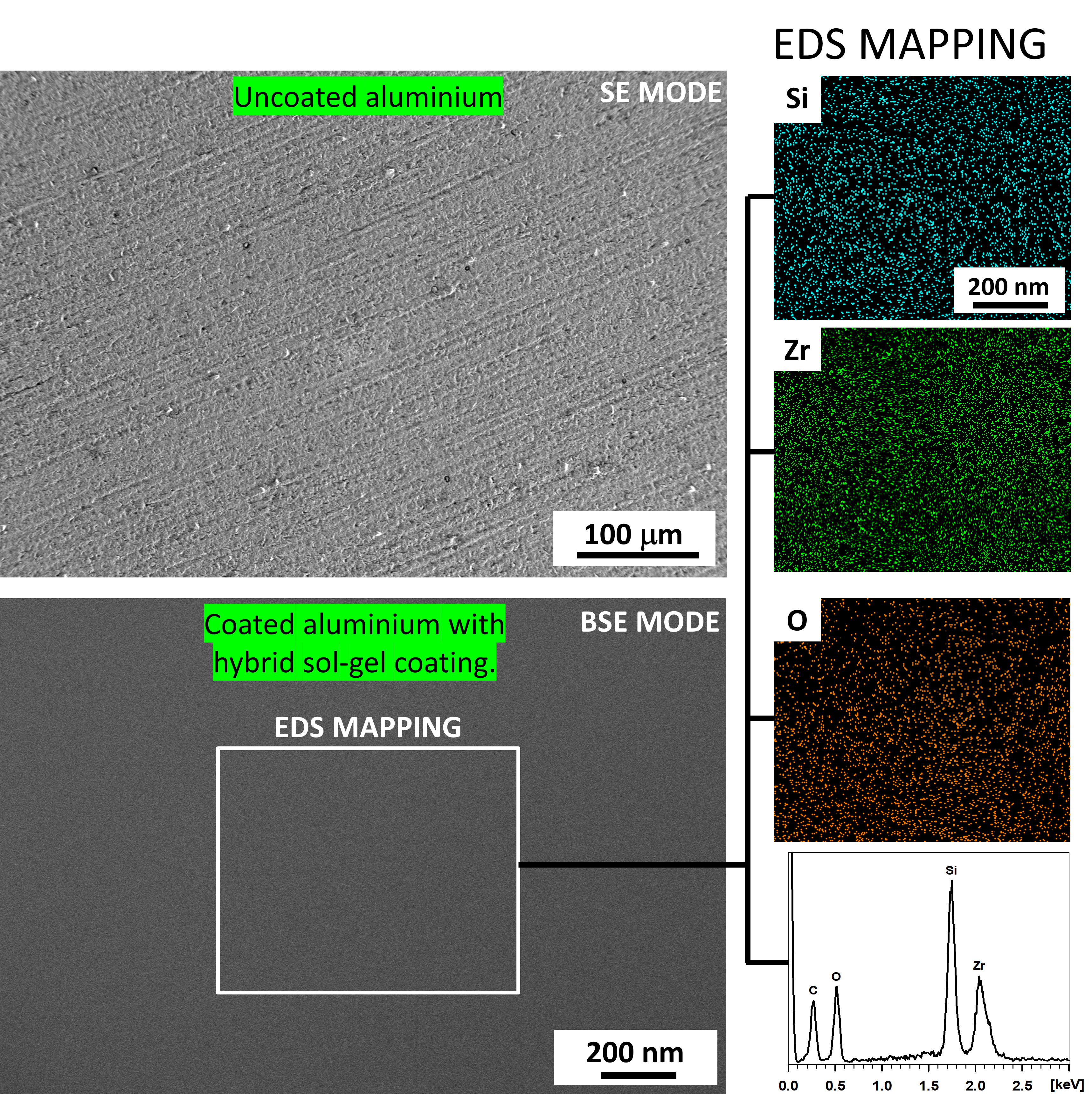

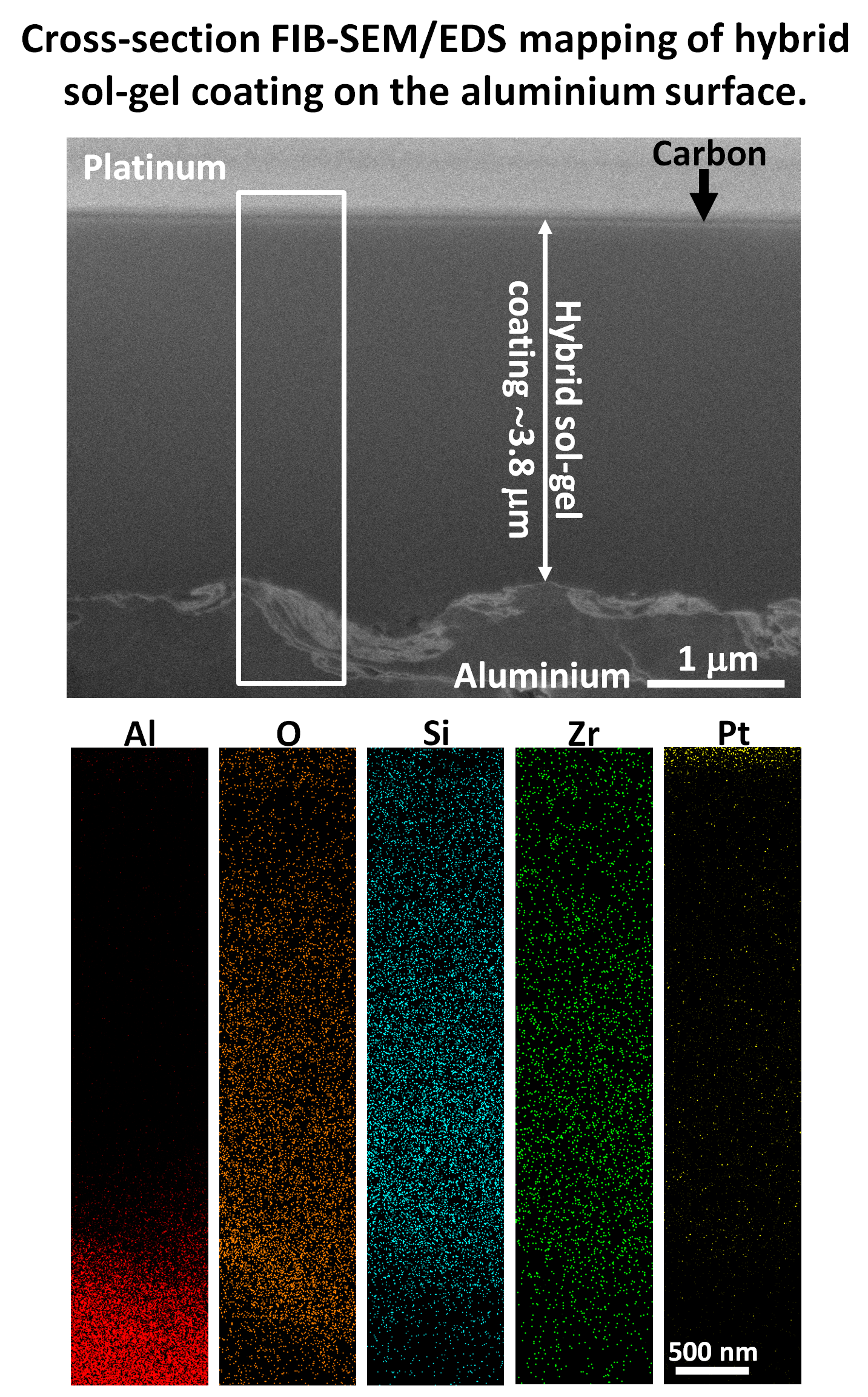

Such an approach gave a better insight into the anodisation processes, and the KET TCs’ experience in the corrosion protection coating development and characterisation in the laboratories brought about new ideas. Active corrosion protection with cerium salts and hybrid materials are the future of a novel coating system. The final coatings assure efficient active corrosion protection, which is an important improvement compared to the traditional sealing process. Based on the successful cooperation within the Project, there is no doubt that the collaboration between Gabrijel Aluminium and KET TCs will continue in the future.

The KET TCs have performed the characterisation of the current and optimised anodised systems with specific laboratory equipment. These actions gave us reliable novel information on the surface composition and corrosion process during the exposure to the corrosive environment. Additionaly, KET TC suggests the novel idea of surface pretreatments ready for further optimisation and upscaling. The cooperation will probably continue in the future on similar projects because joint collaboration gives us faster and better look in the production process.