Stelem d.o.o.

Alternative process for producing metal electrodes on ceramic electronic components

About the company and the project impact

Stelem is a Slovenian producer of ceramic passive components (PTC thermistors, PTC sensors, ceramic capacitors, heating and protection devices, etc.), used for different electronic devices, regulating and industrial technology, electromotors and generators, automotive applications, household appliances, and telecommunications.

Within the Project, an alternative process for producing metal electrodes on ceramic electronic components was implemented. The replacement of the existing screen-printing technique with the aerosol deposition method makes a tremendous impact on the manufacturing of electronic ceramics components. The alternative aerosol deposition process does not involve a high-temperature thermal treatment (up to around 900 °C). That simplifies the entire manufacturing process and makes it much more energy-efficient. Moreover, the use of hazardous organic solvents is also eliminated.

Stelem d.o.o., SloveniaKET Technology

- Advanced Materials

- Advanced Manufacturing

Countries involved

- Slovenia

- Hungary

Outcome

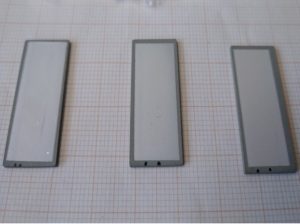

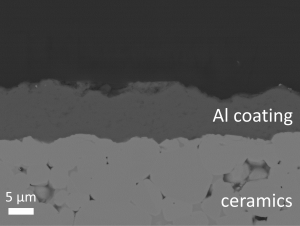

Multiple metal powders that are commercially available were tested in the aerosol deposition process. The aerosol deposition method, used typically for the deposition of ceramics, is appropriate also for metal deposition. Metal coating deposited in that way has a high density, which is achieved without any high-temperature thermal annealing. The aerosol deposition produces metal electrode coatings with appropriate mechanical stability and electrical performance comparable to or even better than conventionally prepared screen-printed thick-film electrodes.

Simultaneously, the process parameters were optimized (gas flow rate, the pressure difference between the aerosol and deposition chamber, deposition time, and amount of initial powder). The quality of the successfully deposited metal (aluminium, copper, and zinc) coatings were evaluated by mechanical, microstructural, and electrical characterization.

Key success factors

Efficient communication ensured the sharing of theoretical and technical expertizes between the SME's and the TCs' project team members. Good cooperation was, therefore, a key success factor in the project.

The implementation of the aerosol deposition technique in the manufacturing process was a complex task, which succeeded because of previously gained experiences on the aerosol deposition of different coatings, careful optimization of process parameters, and advanced characterization of newly prepared few micrometre thick metal coatings by aerosol deposition.

Corresponding KETs Technology Centre:

Jožef Stefan Institute | Ljubljana, Slovenia

Bay Zoltán Nonprofit Ltd. for Applied Research | Budapest, Hungary