Plamtex Int. Ltd.

Improved planning of manufacturing processes for individualized tools

About the company and the project impact

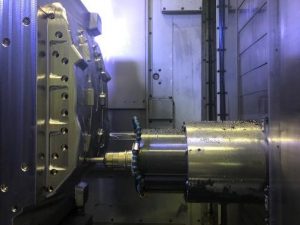

Plamtex is the Slovenian fastest-growing company in the sphere of injection moulding and rubber industry. The company is equipped for producing various plastic parts from standard plastic parts, inserting moulding, 2K moulding, applying different coatings on parts, controlling, coordinating, and monitoring the process remotely. The company also produces moulds for parts with high tolerances and visible parts for rear lights for several premium auto brands.

Within the KET4CleanProduction project, the company improved the estimation of operation durations in the manufacturing of tools for injection moulding of thermoplastic elements for the automotive industry. The new solution will be able to reduce the production costs both in the manufacturing of tools and final products. Reduced waste generation of defective final products will lower the labour costs and the consumption of energy and material while generating less overall pollution. Also, it is expected to increase the sales of final products with higher profitability due to better estimates of the delivery times.

Plamtex Int, Ltd., Slovenia | www.plamtex.siKET Technology

- Advanced Manufacturing

Countries involved

- Germany

- Slovenia

Outcome

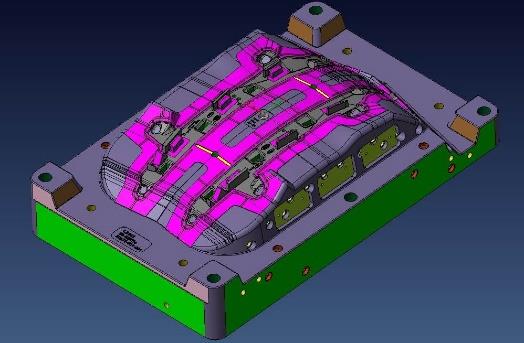

Instead of classic statistical methods, the key step of the solution was the use of Artificial Intelligence (AI) techniques in particular data mining methods, for building predictive models capable of estimating the duration of the operation.

The sources of information for building the predictive models are the features extracted from CAD drawings of the tools, information on actual operation durations available in the technological database, and the expert knowledge on planning the tool manufacturing. The resulting predictive models now assist the experts in the company by providing the estimated operation durations that the experts can further refine. That way, more realistic planning of tool manufacturing takes place, and more competitive offers are prepared for the customers.

Key success factors

Close collaboration and regular meetings of the SME's and TCs' project team members, availability of data and expert knowledge needed for the machine learning phase of the project, flexibility of the participating groups to successfully tackle the unforeseen challenges, and willingness of the involved ICT experts to learn the basics of the application domain and the experts from the company to understand the requirements of the applied methodology were the key success factors of the Project.

Corresponding KETs Technology Centre:

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V | Stuttgart, Germany

Jožef Stefan Institute | Ljubljana, Slovenia