MotilityCount Aps

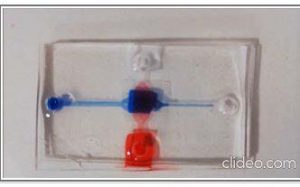

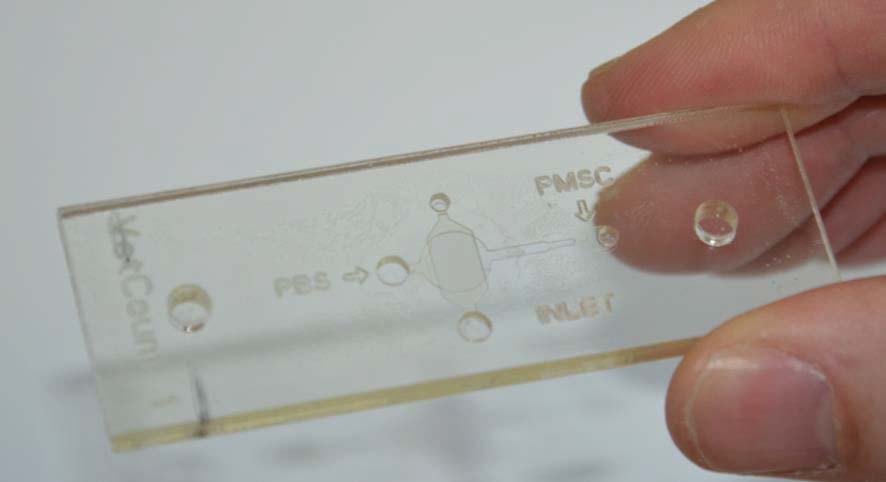

PMSCs selecting microfluidic chip

About the company and the project impact

MotilityCount Aps, a company from Denmark, was founded in 2010 by experienced entrepreneurs and researchers working on in vitro fertilisation (IVF). Prior to its involvement in the KET4CP project, MotilityCount was producing its microfluidic chips to evaluate the quality of the sperm cells with a patented method through injection moulding. However, to be able to include a membrane filter into a microfluidic cell, polycarbonate plate has to be milled manually, while the filter is required to be glued, resulting in the hindrance of the microfluidic flow, the inaccuracy of the microfluidic system, and the waste generation of a large amount of defected microfluidic chips.

The KET4CleanProduction project made it possible for the company to use a microfluidic platform with integrated filters and known plastic moulding technologies to produce the chips that ensure a potential quality validation in 99% of the pieces produced. The alternative would have been a hand-made/machined device that would be very expensive to make. Through ensuring the proper functioning of the company’s device, Motility Count will provide farmers with a device that can reduce the reproductive loss in their farm animals by up to 25%.

MotilityCount Aps, Denmark | www.swimcount.euwww.vetcount.comKET Technology

- Advanced Manufacturing

- Micro-/nano-electronics

Countries involved

- Denmark

- Spain

- Germany

Outcome

The main outcome of the project was the design of a microfluidic system that can include a PC filter without impacting the microfluidic flow. The optimisation of VetCount has allowed the company to provide a smaller version and an optimised solution, including micropumps that will reduce the amount of material during their scale-up process, avoiding the amount of both raw and waste materials.

Through passing from manual milling and glueing to injection moulding, the consumption of energy per device has been reduced by 350%. That is linked directly to the company’s production costs. The moulding process development drastically increases the throughput, reduces human intervention (better reproducibility), as well as the number of steps for the fabrication. Compared to the current manufacturing process, tolerance will increase, and filters will be assembled easily, which results in a better and more robust microfluidic flow. Moulding enables the production of ~15,000-20,000 devices per month while keeping setup costs low and providing little inter-device variability.

Injection moulded device

Hand fabricated device

Improved device

Key success factors

The key success factor of this project was the efficient communication and cooperation with the KET TCs.

The company had a core design challenge, and that was to include filters into the microfluidic structure. The KET TCs helped solve that problem. The company is now testing the first of the tools that are based on the design generated by this project.

Corresponding KETs Technology Centre:

Leitat - Technological Center | Terrassa (Barcelona), Spain

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V | Stuttgart, Germany