Ferročrtalič d.o.o.

Advanced environmentally friendly surface treatment for aluminium and aluminium alloys used in the aircraft industry

About the company and the project impact

FerroČrtalič, a family company with 55 years of tradition, focuses on developing solutions and producing machinery for surface treatment technologies under registered trademark FerroECOBlast Europe. The company provides the best possible surface treatment solutions for its customers worldwide. The primary aim of the company is to advise, present the latest technology solutions and produce (manufacture) equipment for surface treatment.

The primary goal of the company was to approach the global problems related to the replacement of chemically-based, potentially hazardous surface treatments with environmental-friendly, low-cost substitute technologies. Within the KET4CleanProduction project, the company focused on the development of the advanced technological surface pre-treatment technology in the production process for aluminium and its alloys and the formation of the conversion coating based on zirconium (ZrCC) used as a primer to improve corrosion protection. These advanced surface treatments use no chemicals and produce no side products. Used materials can be recycled and reused in the system. Consequently, there are foreseen reduced impacts on health and the environment. The developed technological solution can have a cross-border industry impact on other manufacturing companies, thus increasing their competitiveness and reducing the generation of pollution. Due to the increased durability of aluminium, this will also affect safety in the aviation industry.

Ferročrtalič d.o.o., Slovenia | www.ferroecoblast.comKET Technology

- Advanced Manufacturing

- Advanced Materials

Countries involved

- Slovenia

- Austria

Outcome

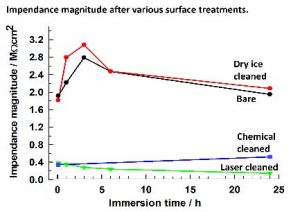

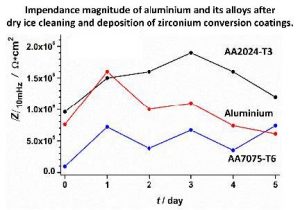

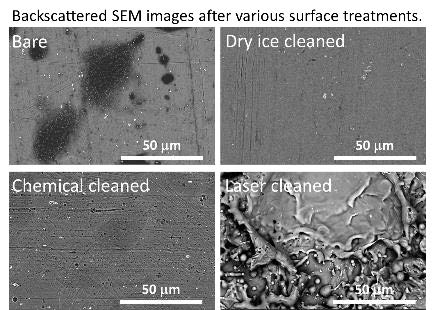

The innovative technological solution introduced shot peening and dry ice cleaning into the pre-treatment technology to enhance the mechanical properties and corrosion protection obtained with ZrCC. These technologies are not only low-cost, easy to use, and non-hazardous to the environment but also reduce the reliance on raw materials. The XPS, SEM/EDS, and TOF-SIMS data obtained during surface characterisation before and after various surface treatment explain the mechanism of the surface cleaning process with dry ice and subsequent formation of ZrCC on the aluminium surface. Electrochemical measurements enabled the characterisation and understanding of the corrosion process to determine the quality of the surface without and with pre-treatment.

The evaluation of chemical composition, morphology, roughness, micro-hardness, and wettability was carried out to characterise the physical and chemical properties of the surface. Corrosion tests in the salt spray chamber were performed under the industrial standards. All those results aimed to confirm the production quality of the pre-treated and protected surfaces.

Key success factors

The key success factor of this project was the multidisciplinarity of the company and KET TCs' laboratories. All groups have had previous experiences with technical issues in the aircraft industry, especially in the surface pretreatment of aluminium alloys. However, the problem could be solved in its complexity only when approached in a multidisciplinary manner.

A systematic approach gave many important quantitative and qualitative results to consider the possibility of the use of environmentally acceptable advanced surface pretreatments for further development as a part of novel corrosion protection technology. The SME needs to outsource laboratories with specific high-tech technology for developing new technologies to remain competitive on the market and fulfil all environmental restrictions. The collaboration between the Ferročrtalič and KET TCs will continue in the future.

Corresponding KETs Technology Centre:

Institute Jožef Stefan | Ljubljana, Slovenia

Joanneum Research Forschungsgesellschaft mbH | Graz, Austria