UNITEQ s.r.o.

success story

Development and assessment of the mixing of plastic waste to the coal charge in the cooking process for energy production optimisation and environmental pollution reduction

UNITEQ s.r.o. is a Slovakian company operating in the field of automation of control systems, production, technological, and information systems. The company has years of experience in the development and delivery of various IT projects for manufacturing systems in the metallurgical industry and the automotive industry.

The data collected during the KET4CP project in terms of experimental results, laboratory and modelling analyses have allowed the company to investigate in detail the process of adding plastic to the coal charge in a coke oven. That reduces the need for plastics disposal facilities, which are often associated with regional management issues. The process option developed within the project is of great interest in an integrated waste management framework, allowing the exploitation of existing facilities without significantly altering their environmental impact.

KET Technology Centers involved

- Seamthesis | Italy

- RECENDT | Austria

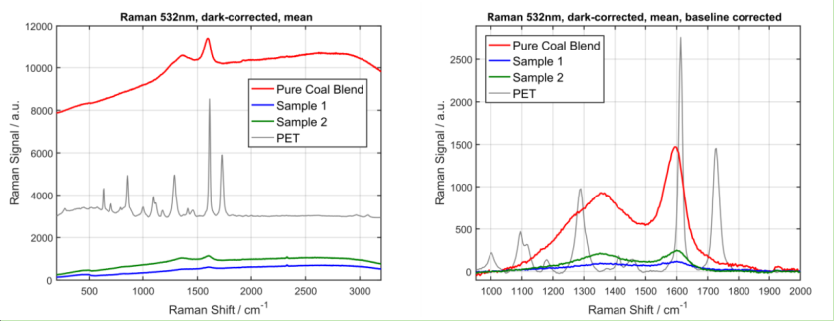

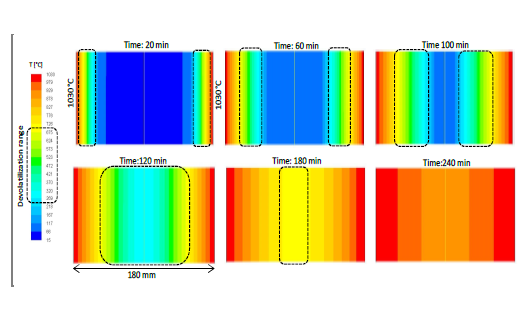

It has been verified both theoretically and experimentally that it is possible to add plastic up to a certain limit without significantly affecting the quality of the coke produced and the composition of the gas extracted in terms of emissions. The project verified that 1% plastics by weight could be added to the coal charge without significantly altering the process and the produced coke.

Considering that a coking plant can process more than one million tons per year of coal, tens of miles of tons of plastics are potentially disposable in the coking plant. A significant aspect concerned the verification of the pre-treatment of the plastics that could be a bottleneck in the implementation of this modelling option. Shredding with a standard mill yields plastic sheets of a few millimetres suitable for mixing with coal. Further treatments to reduce the size do not improve the yield and quality of the coke produced.

The critical analysis of the available references targeted verification tests in combination with the advanced laboratory and modelling analyses have allowed the partners to highlight all the peculiarities of the process and to identify the ways to implement this option at the industrial level. With the help of TCs, the results have led to the identification of guidelines for the optimal industrial implementation of the plastics disposal technique.