Sunplugged GmbH

success story

Missing Ink

The Austrian SME Sunplugged develops and manufactures flexible thin-film solar cells for the integration into devices and building skins. Sunplugged’s approach is based on a proprietary, high-efficient CIGS solar cell and a printed interconnection that allows the production of Photovoltaic modules in the fashion of mass-customisation. The so-called Monoscribe interconnection from Sunplugged exploits the advantages of a deferred serial interconnection of film-based solar cells.

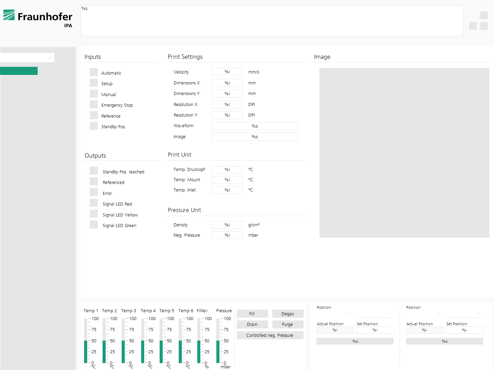

The main objective of the Missing ink was to develop a suitable inkjet print engine that can be integrated into the Monoscribe Roll-to-Roll pilot line. Both the laser process and the application of the dielectric and conductive materials can be controlled digitally, which allows producing photovoltaic modules with differing sizes, geometries and output voltages “on-the-fly” without excessive set-up times. The technology has been developed within the KET4CleanProduction Pilot project and successfully tested in batch mode.

KET Technology Centers involved

International Iberian Nanotechnology Laboratory | Portugal

IPA - Fraunhofer Institut für Produktionstechnik und Automatisierung | Germany

The involed TCs did a great job. They helped us to develop and design an additive manufacturing platform for further upscaling and validation of our novel interconnection technology in an Roll-to-Roll environment.

Sunplugged has developed a novel interconnection scheme that fosters advancements in laser scribing and additive manufacturing for film-based photovoltaics.

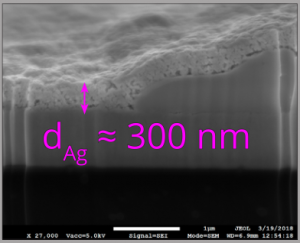

The so-called Monoscribe interconnection exploits the advantages of a deferred serial interconnection of film-based solar cells. Within the pilot project, the TC Fraunhofer IPA designed and developed the printing framework that was urgently needed to upscale the interconnection technology, while the collaboration with the INL provided insights into potential causes for performance losses in the printed interconnection.

The project had the full support of the involved TCs, with engineers and researchers motivated to help the SME solve the technical challenge.

The cooperation and the whole project helped the SME to learn and expand its expertise in additive manufacturing. Furthermore, the project gave insights into potential performance losses that occur when applying the printed interconnection.