Organska Elektronika

success story

Low-cost microfluidic cartridge for the detection of mycotoxin in food to be used in a point-of-care device

Organska Elektronika d.o.o. (OR-EL) is a Slovenian start-up company founded by two international researchers. The company deals with research and development of multi-parametric diagnostic tools with a specific focus on OLED technology.

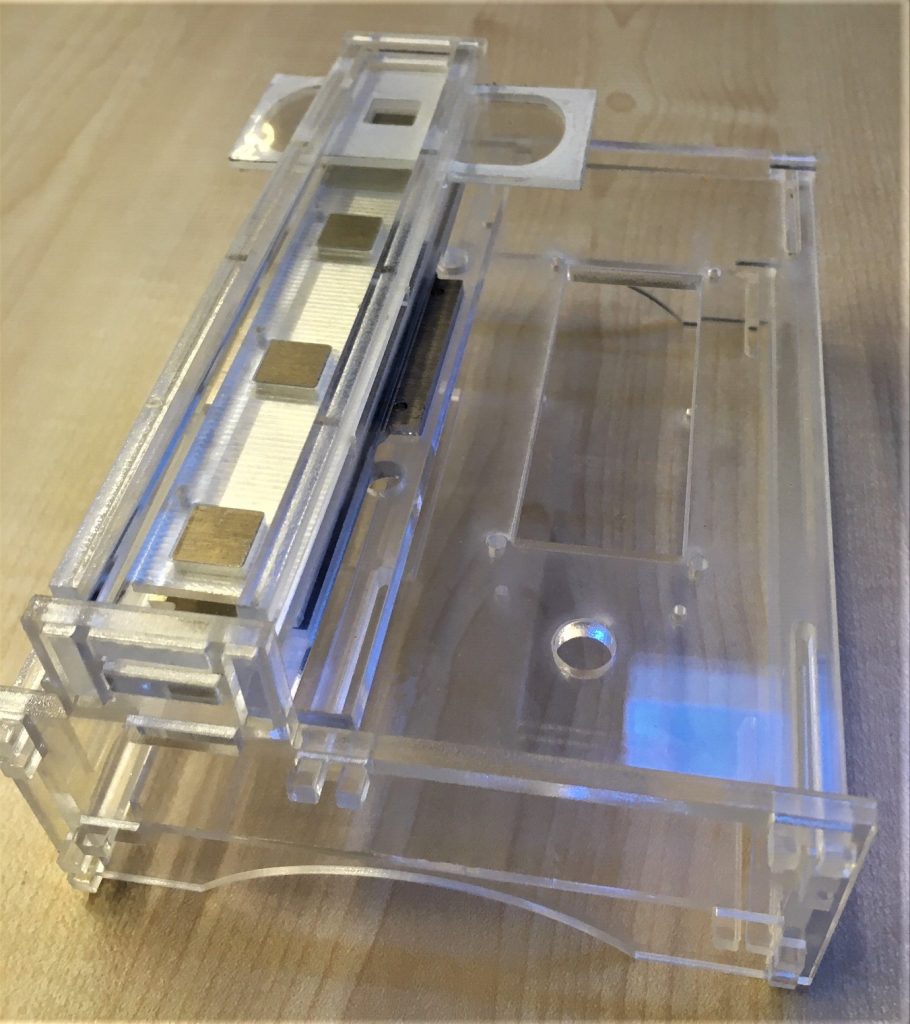

The goal of this project was to optimize the manufacturing of the plastic cartridge to be used in a so-called ‘’immunofluorescent competitive test for the detection of mycotoxin in milk’’. The so-called aflatoxin M1, which is a very powerful hepatocarcinogenic agent, can accumulate in the human liver and incite liver cancer even at low levels. The OR-EL technological platform has been developed to implement a Point of Care (PoC) diagnostic system for the detection of different analytes in a liquid matrix. The disposable slide design and implementation, developed within the KET4CleanProduction project, is environmentally sustainable as it lowers the amount of plastic needed for the analysis. It reduces the number of plastic vials needed to run an analysis. Also, the overall amount of plastic needed to fabricate the disposable slide is reduced by 10%. Furthermore, by using the analysis method, the amount of the reagent is reduced, and since the disposable cartridge is a closed system, all the waste is kept on board and will not disperse into the environment.

KET Technology Centers involved

INL -International Iberian Nanotechnology Laboratory | Portugal

Hahn-Schickard-Gesellschaft für angewandte Forschung e.V | Germany

The project aimed to develop a plastic cartridge suited to on-field biological diagnostic (point-of-care) when coupled with a portable incubator and a portable reader.

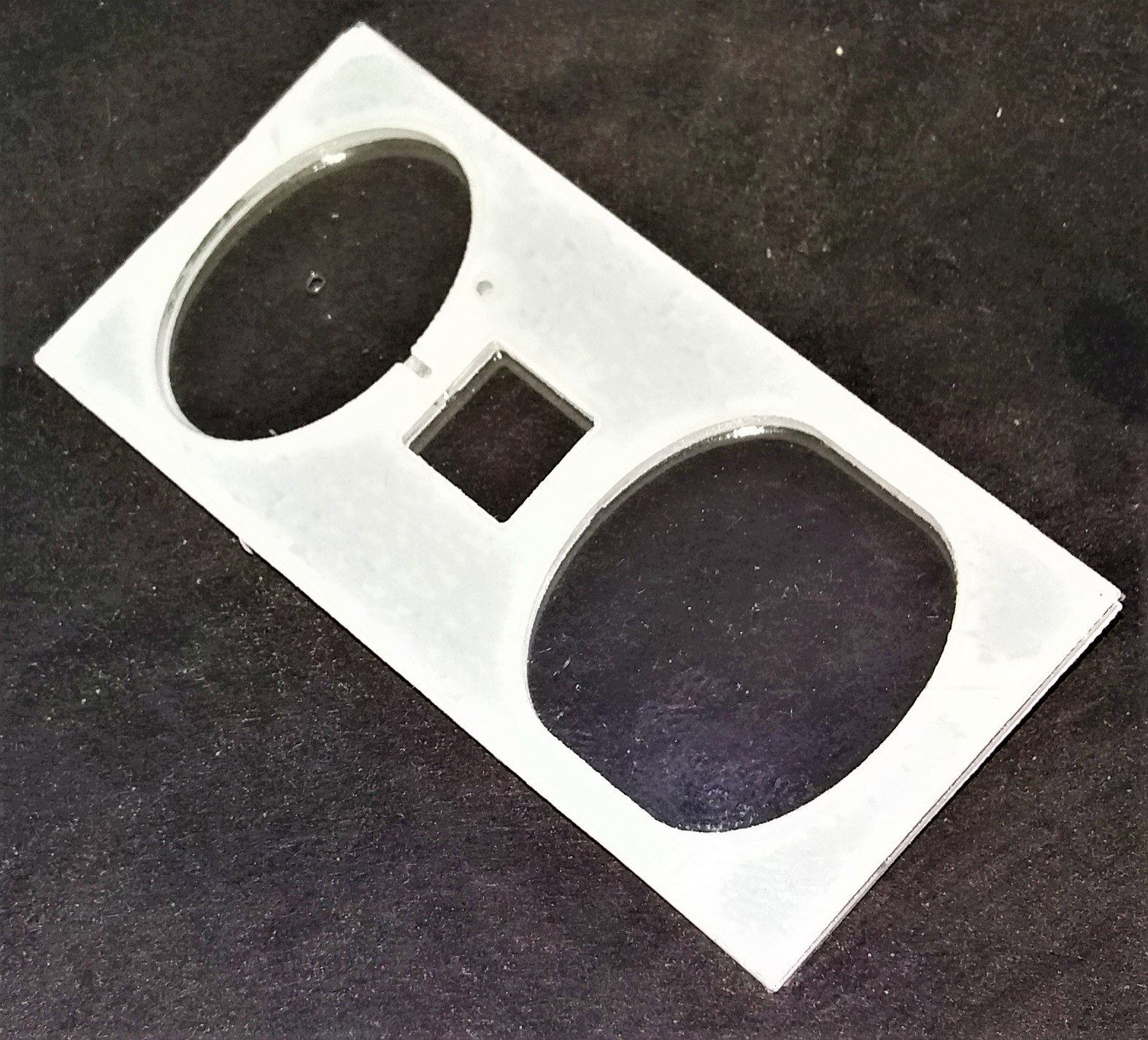

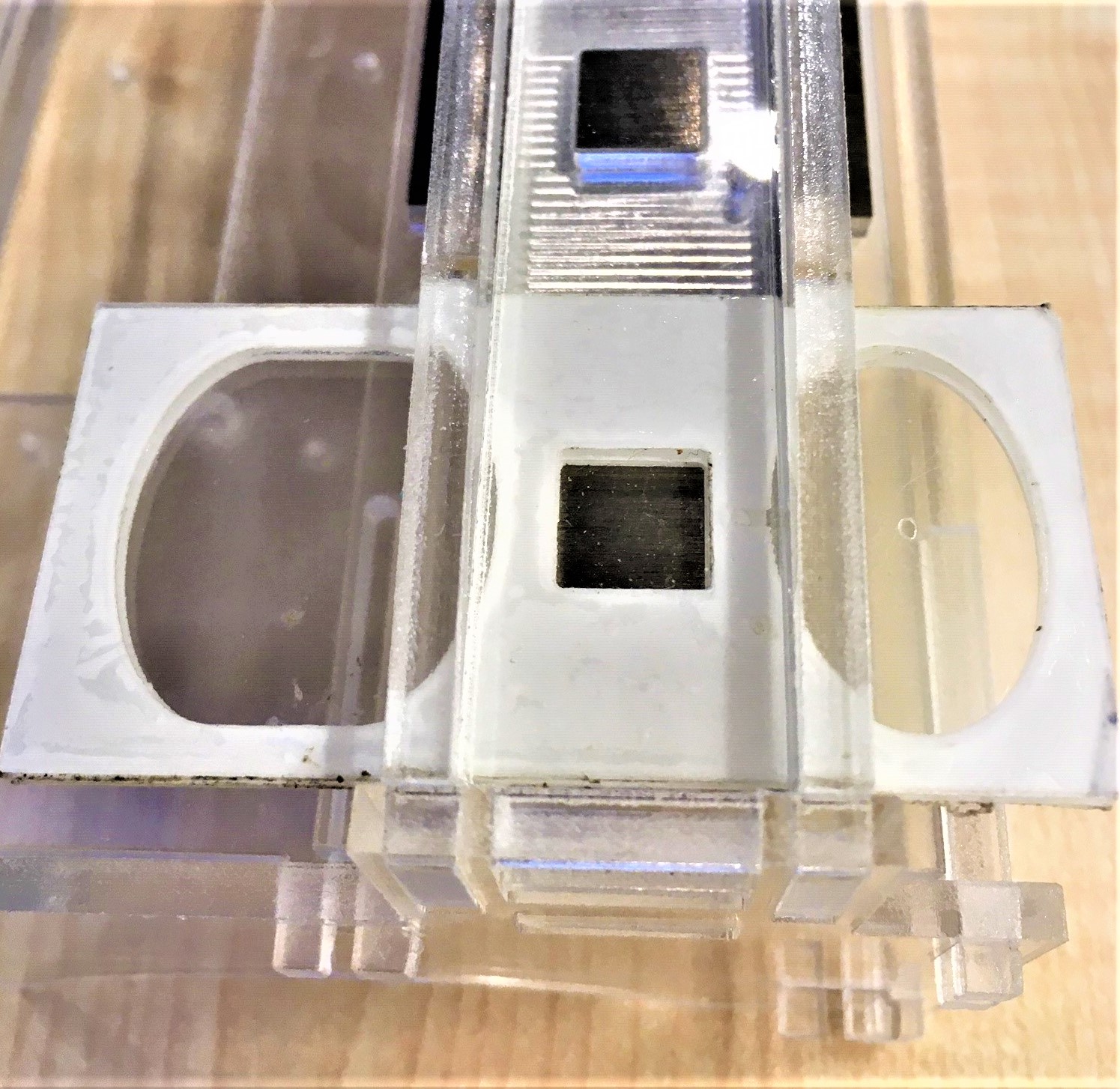

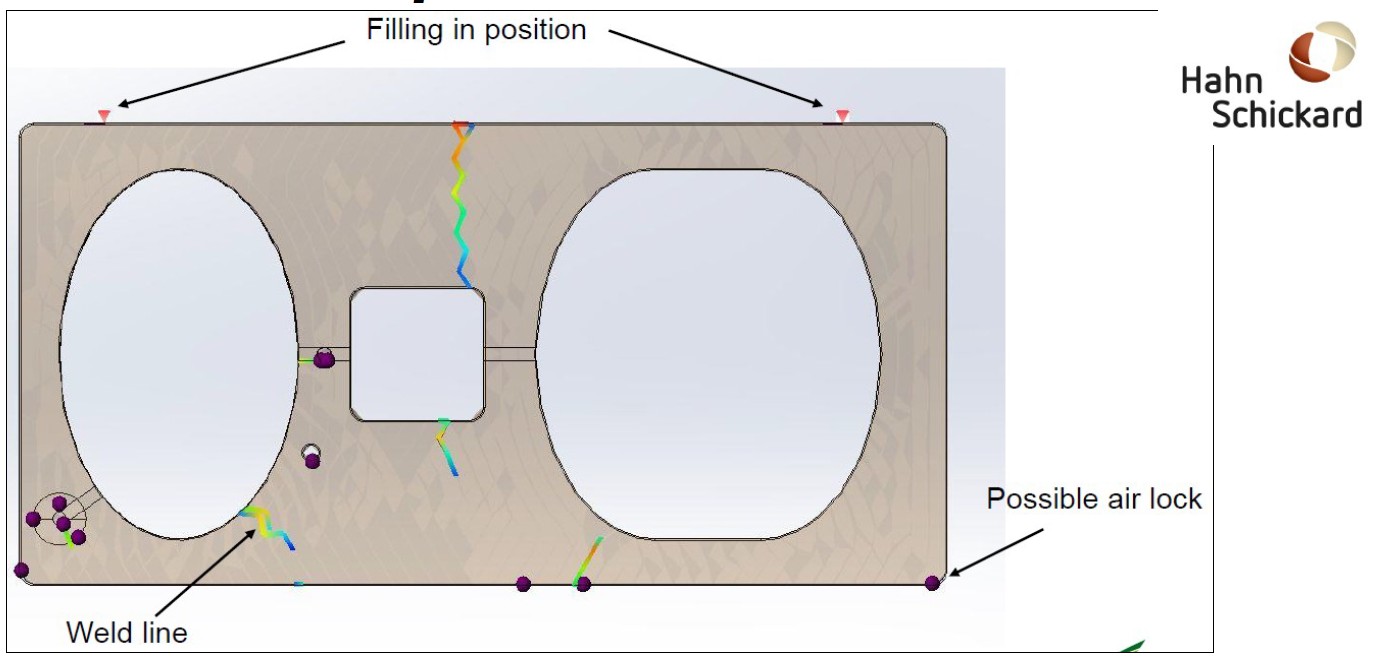

A plastic cartridge with three chambers has been designed and produced as a prototype after several optimisation steps. The main outcome was the newly designed cartridge, which can be produced using the injection moulding technique, allowing cost-reduction in its mass-scale fabrication while reducing plastic consumption. Also, other mass-production techniques for the bonding of the transparent substrate to the injection-moulded plastic frame have been investigated, and possible solutions have been found. That will allow simplifying the cartridge production while saving time and energy. The developed portable reader will allow processing more cartridges at the same time while reducing analysis time as well as its reproducibility.

Access to competencies and knowledge that are not available within the company, and the competencies and skills of both KET TCs included in the Project, were instrumental to the achievement of the objectives.

Both TC Partners effectively addressed the issues presented in the Proposal, and the company had an excellent sharing and working experience with the Partners, who proved to be highly competent and available.

The KET4CP Project represented for our company a really good opportunity and experience. Getting in contact and then working with highly skilled European companies and institutes was a major breakthrough in the development path to our final Product.