MPT Ltd.

success story

Machine vision quality control of molded plastic parts

MPT Ltd. is a family-run company with more than 30 years of experience in plastics processing and moulding. The manufacture mostly involves technically highly demanding products made in large batches for both the foreign and domestic markets. The wide range of products includes products for the industry of small domestic appliances and household appliances, products for the furniture industry, products of mass consumption, products for the environmental industry, and products for the electrical industry.

The KET4CleanProduction Pilot project was used for finding the solution for automatic quality control at the end of the moulding process for a plastic gear wheel, typically used for home appliances, which is produced in large quantities. The main improvement was that each product is now inspected and manipulated by the robot during the entire production process, starting with the production tool and ending with the packaging box.

The MPT d.o.o. company production hall

KET Technology Centers involved

Josef Stefan Institute | Slovenia

Leitat - Technological Center | Spain

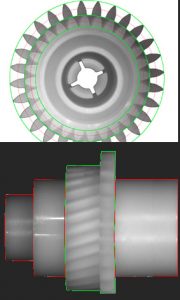

During the moulding process and the ejection from the machine, various defects can appear on the plastic parts, which were checked manually before. Within this Project, an automatic machine vision inspection and manipulation system were specified and verified.

Those can now manipulate eight products from the moment they are produced to the moment they are individually inspected and classified as good of faulty. The integrated machine vision quality leads to several benefits, such as cost and error reduction, accuracy, productivity, increase in overall efficiency, and collection of statistical data.

An injection moulding machine where the plastic worm wheels are produced

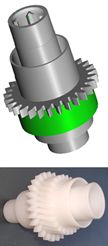

The worm wheel (bottom) and its 3D CAD model (top)

Testing environment for machine vision components

Feature-extraction-for-the-worm-wheel-automated-surface-control

Support received from the involved KET TCs, researchers, and engineers, as well as their motivation for finding the best possible solution, were the key success factors. The Project helped the company upgrade its knowledge about machine vision technology and learn the possibilities of its future growth.