INNOWEAR-TEX Kft.

success story

Environmentally friendly antimicrobial material for textile with improved properties

INNOWEAR-TEX Ltd., founded in 2008, is a Hungarian company concentrated on the development and production of innovative and intelligent clothing. Their products are based on the latest research and development results in order to support a comfortable and healthy lifestyle and protect the environment by providing sustainable development. The company is currently using nanosilver for providing antimicrobial activity on its circular knitted fabrics and protective clothes.

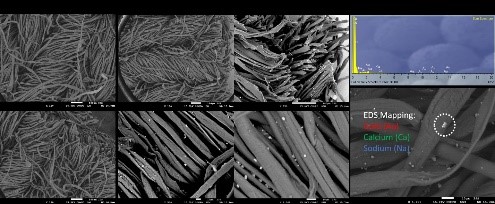

The KET4CP project was focused on replacing silver-based technology (releasing antimicrobial components) in antimicrobial textile with an alternative, less toxic solution. The classical technology has been effectively replaced with environmentally, ecologically, and human-friendly alternative, contact-based nano-gold technology following standard procedures used in the textile industry regarding the application.

KET Technology Centers involved

- Jozef Stefan Institute | Slovenia

- CITEVE | Portugal

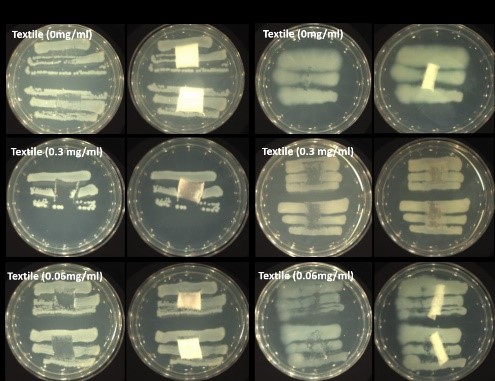

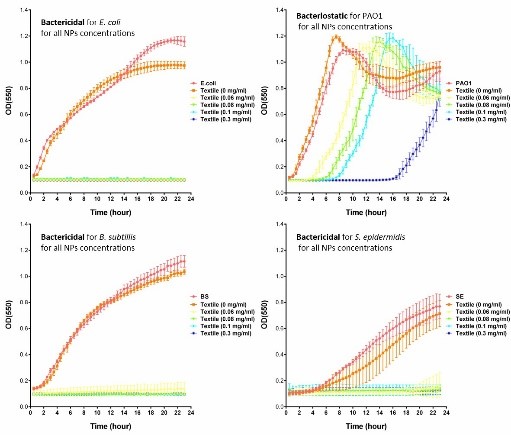

The technology has been effectively optimised and incorporated into textile at the laboratory level, as well as scaled up to pilot level reaching final TRL6. The newly developed technology has an important contribution to its safety without compromising its efficacy, and the strong bactericidal nature of the textile's action, which was tested on four different bacteria strains, and four different textile types were kept even after 20 washing cycles.

In addition to antimicrobial activity, antiviral activity was also obtained due to possible applications for limiting COVID-19. Replacing the toxic silver-based technology with gold-based nanotechnology is a safer solution for reaching an antimicrobial effect on textiles. Bonding of gold-based nanoparticles to textile can be reached by using direct, less chemical-intensive methods. The project implementation leads to the reduction of waste generation by 80-90% and reduces the generation of pollution by 80-90%

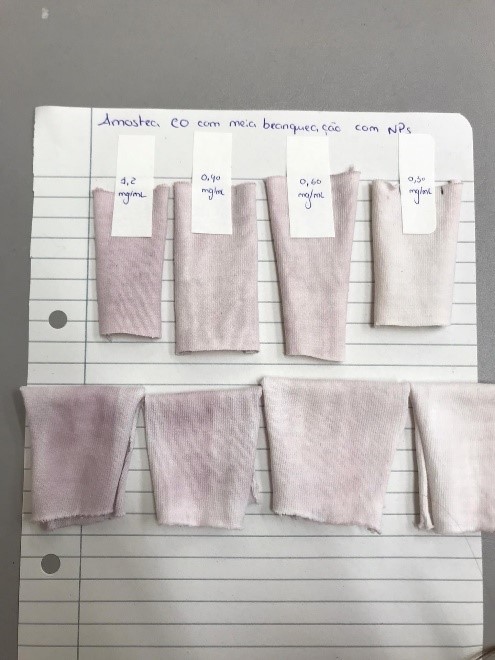

The new, more environmentally, ecologically and human friendly antibacterial treatment was successfully and effectively applied on our fabric, therefore we consider this project a great success. Since the treatment has some effect on the colour of the fabric, our next goal will be to continue this fruitful cooperation and with the improvement of the results, create an excellent product which serves the welfare of others.

Collaboration with both project partners was extremely useful and innovative. Professional management of both KET TCs contributes to the fact that all of the planned tasks and work packages were carried out successfully.

Furthermore, with their help, the test results showed that the replacement of toxic antimicrobial treatments is possible with a less toxic and more environmentally, ecologically, and human-friendly alternative providing a similar antimicrobial effect.